In our continuous quest to enhance processes and add value, Lean methodology has consistently proven to be a powerful tool, backed by decades of successful application and measurable results.

Statistics reveal that companies implementing Lean Manufacturing experience significant cost reductions, productivity gains, and improved customer satisfaction.

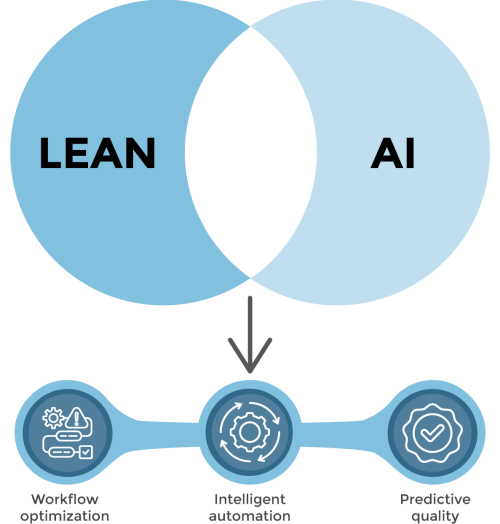

With the increasing integration of Artificial Intelligence in business processes and operations, Lean methodologies are undergoing a profound evolution. AI, through operational research, offers new ways to optimize processes, automate repetitive tasks, and enhance organizational decision-making.

Combining Lean principles with AI has the potential to revolutionize our operations, and we’re here to explore this synergy.

What is Lean methodology?

Originating in the Japanese automotive industry, particularly in Toyota’s production lines, Lean methodology focuses on a fundamental principle: the elimination of waste. It posits that any activity or process not adding value to the end customer is considered waste. By utilizing tools such as just-in-time, Kaizen, and value stream mapping, organizations can identify and eliminate inefficiencies, achieving more agile and effective operations.

Lean is more than just a set of techniques; it’s a philosophy that fosters a culture of continuous improvement. By empowering employees and encouraging a mindset of constant questioning, Lean transforms the internal structure and dynamics of organizations. True change occurs when everyone, from executives to shop floor workers, embraces these principles and works collectively towards operational excellence.

The Intersection of Lean and AI

Artificial Intelligence, through operations research and big data analytics, enhances problem-solving and decision-making in organizations. AI focuses on identifying optimal solutions for organizational challenges using probability, statistics, optimization, and simulation. It has become crucial for strategic and operational decisions, enabling predictions, risk measurement, and resource optimization, which are essential for boosting productivity and efficiency.

Integrating AI into Lean methodology adds a new dimension, as AI can provide deep, actionable insights into processes, uncovering information invisible to humans.

Workflow optimization

One of the most evident applications of AI in Lean is workflow optimization. Machine learning algorithms enable organizations to analyze performance patterns and predict bottlenecks before they occur. This proactive approach allows for precise planning and better resource allocation.

Intelligent automation

Automation is a key component of Lean, and AI elevates this capability. Smart machines can execute repetitive tasks with unmatched precision and efficiency, freeing employees to focus on higher-value activities. Furthermore, AI, through machine learning and deep learning, endows systems with the ability to learn and adapt to process variations, ensuring optimal operations even as conditions change.

Predictive quality

In a Lean environment, quality is paramount. AI can significantly enhance quality control through predictive analytics. By identifying patterns and anomalies in production data, AI can forecast defects and failures before they happen, enabling early interventions that minimize waste and ensure high-quality products.

Do you want to stay updated with blogs like this? Subscribe to our bi-monthly Newsletter.

Despite the great advantages that AI brings to enhance and improve Lean processes, it does not replace the intrinsic value of human creativity and intuition. Instead of viewing AI as a standalone entity, we should consider it an extension of our capabilities, a tool that amplifies our ability to solve problems and make informed decisions.

The integration of Lean methodology and artificial intelligence implies a radical transformation that redefines organizational efficiency and innovation, taking organizations to new levels of performance and competitiveness.

Would you like to know how to apply AI in your organization? Schedule a meeting with us.