The aeronautical industry has participated in digital solutions since its appearance, but not all. Acronyms like CAD, PLM, ERP, MES etc. are well known in the sector, whose companies have been implementing commercial tools as they emerged. However, prescriptive analytics has been largely absent from the sector’s transition towards the 4.0 paradigm, in particular the area of production planning and scheduling.

This is the justification for the research carried out by Tamara Borreguero and collected in her PhD dissertation “Scheduling with limited resources along the aeronautical supply chain: From parts manufacturing plants to final assembly lines” (whose directors are Álvaro García and Miguel Ortega, founding partners at baobab soluciones).

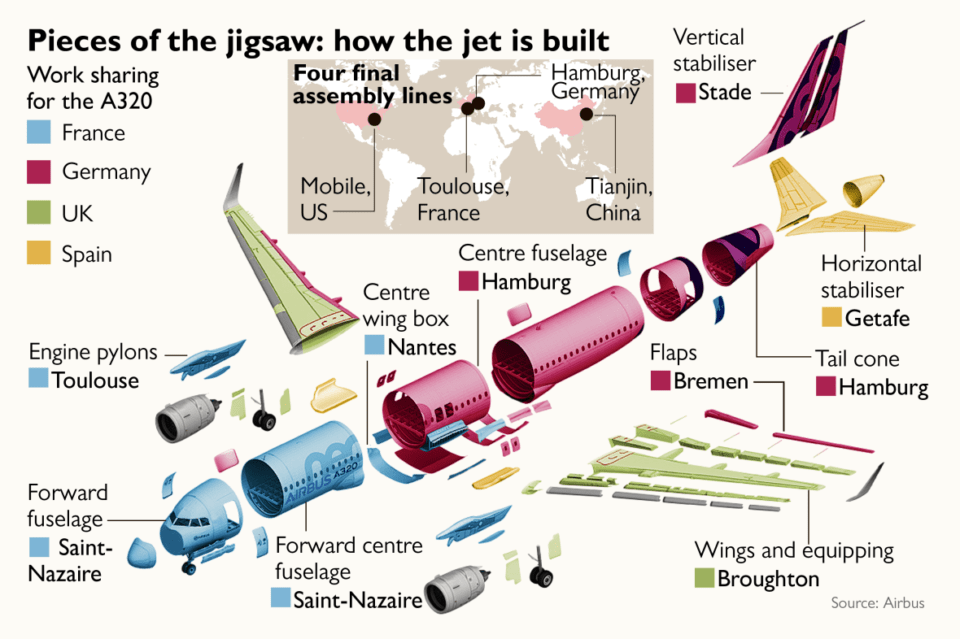

The supply chains of companies such as Airbus and Boeing are extremely complex, due to the plethora of companies that are involved in globally dispersed plants, as evidenced in the image, relative to the supply chain of the A320 models of Airbus.

Effectively and efficiently coordinating all manufacturing, transportation, warehousing and assembly operations is critical to the profitability of aircraft manufacturers. However, this type of task has been traditionally left out of the digital transformation initiatives of the aeronautical sector.

In this sense, Dr. Borreguero’s thesis represents a novel contribution by proposing concrete solutions based on prescriptive analytics to solve various problems related to production planning and scheduling.

Do you want to stay up to date with blogs like this? Subscribe to our Newsletter.

Three main challenges

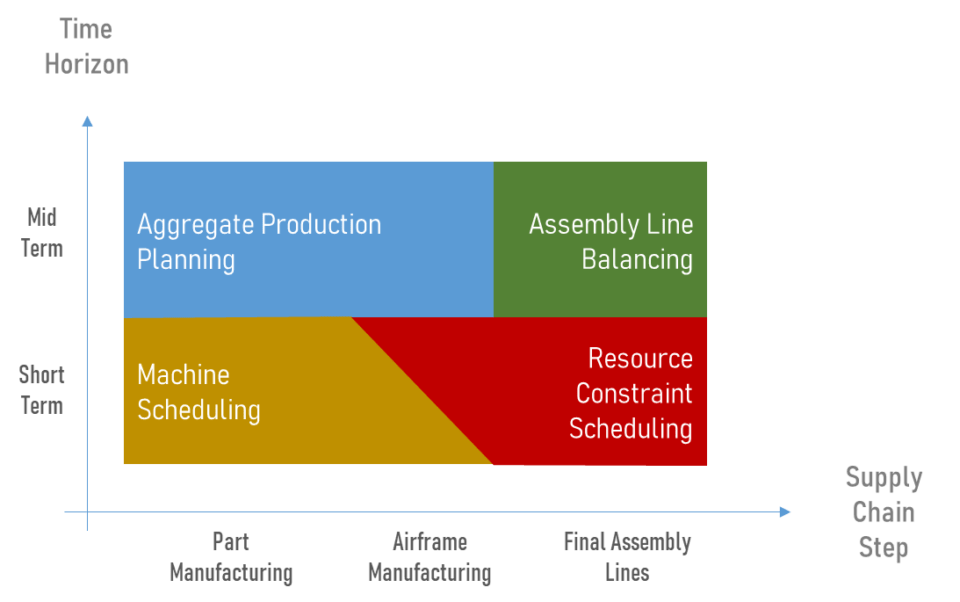

The production of an aircraft goes through three areas: parts manufacturing, assembling aerostructures from the previous parts and aerostructures final assembling. Each of these areas has its own problems, which can be of a diverse nature, strategic, tactical or operational.

The research focused on three major challenges, for each of which a mathematical model and a practical application were developed, which validated the usefulness of the approach adopted in each case.

The first problem was the airframe manufacturing short-term scheduling. The second problem was the mid-term scheduling for airframe manufacturing to correctly size the productive capacity and comply with the delivery schedule. Finally, the third problem dealt with short term scheduling for final assembly lines, so that the operations in each of the workstations are carried out in compliance with the cycle time (takt time) and keeping the least possible consumption of resources.

The results of this research exceed the analysis of these problems and the development of prescriptive analytical models, but rather rigorously demonstrate their advantages, also discussing the practical implications of their development and their integration with the rest of the company’s systems, within the Industry 4.0 paradigm framework.

In summary, this thesis proves how Prescriptive Analytics can improve the aeronautical industry’s supply chain. It provides new knowledge to the scientific community that can be directly applied to the aeronautical sector. It constitutes a good example of how it is possible to work on real industry problems without giving up the rigor of Academia.