How much does your plant’s productivity increase with Intelligent Robotics? How does this new scenario impact your factory costs?Collaborative robotics, driven by artificial intelligence (AI), is transforming the industrial landscape.

Collaborative robots, or cobots, are tools designed to work safely and efficiently alongside humans. These solutions combine manual operation with automation, enabling businesses to maximize the advantages of technology.

A report from Grand View Research estimates that between 2025 and 2030, the global market for collaborative robots will experience an annual growth rate of 31% compared to 2024, when it was valued at $2.1 billion. This surge is fueled by the adoption of cobots in small and medium-sized enterprises (SMEs), which see them as a key solution to address the shortage of skilled labor and rising demands.

These collaborative robots analyze, learn, and adapt to dynamic environments, executing actions autonomously and enhancing their ability to perform complex tasks. This enables companies to create hybrid, competitive environments where humans and robots share the same workspace.

How does this technology work?

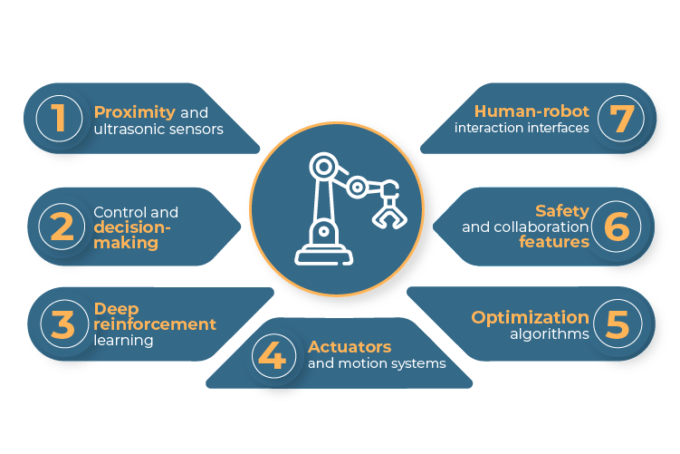

Collaborative robots combine hardware and software components designed to perceive their environment, make real-time decisions, and perform tasks with precision.

- Proximity and ultrasonic sensors: Detects objects and obstacles, ensuring safe navigation and interaction within dynamic environments.

- Control and decision-making: Real-time control algorithms and decision-making systems enable cobots to adapt dynamically to environmental changes.

- Deep reinforcement learning (DRL):Allows cobots to autonomously learn and improve at performing complex tasks with increasing efficiency.

- Optimization algorithms:Maximize operational efficiency, reduce costs, and plan optimal trajectories tailored to specific environments.

- Human-Robot interaction interfaces:Intuitive tools let operators visualize and adjust cobots’ actions in real time, enhancing usability and collaboration.

- Safety and collaboration features:Enable cobots to anticipate and react to unexpected movements from operators, adjusting behavior to prevent accidents.

- Actuators and motion systems: High-precision actuators and feedback systems ensure smooth, controlled movements for accurate task execution.

How do these technologies impact industrial environments?

The implementation of AI-powered collaborative robots (cobots) in industrial environments has shown significant improvements in various key performance indicators (KPIs):

- Reduction of operational costs:The automation of repetitive and high-risk tasks through cobots allows companies to significantly reduce operational costs.

- Increase in productivity and efficiency:The collaboration between humans and cobots not only optimizes workflows but also increases speed and accuracy in task execution. Furthermore, their ability to perform specific tasks with high precision improves overall production outcomes.

- Improvement in workplace safety:Cobots are designed with advanced safety features, such as proximity sensors, force and speed limits, and collision detection.

- Increase in product quality:Cobots provide a high level of precision and consistency in their tasks. This is particularly critical in industries such as electronics or automotive, where even a small mistake can have a significant impact on the final product.

- Reduction in downtime:One of the main benefits of cobots is their flexibility and ease of programming, which allows them to quickly adapt to different tasks and minimize downtime in production lines.

Ejemplos y casos de éxito.

- Manufacturing: The automotive sector already uses cobots for critical assembly tasks, such as installing shock absorbers or seats.

- Electronics Industry: Cobots have been incorporated into the manufacturing of electronic devices, where millimeter-level precision is required.

- Pharmaceutical Industry: In the pharmaceutical industry, cobots are used for dosing and packaging medications.

- Logistics and Distribution: Cobots are employed in distribution centers to optimize the sorting and movement of goods. This automation has streamlined operations and reduced the physical burden on employees.

The integration of collaborative robots (cobots) is transforming the way industries operate, becoming a key piece in the industrial future.

Human-cobot collaboration enhances productivity and creates a safer and more efficient work environment, where employees can focus on higher-value tasks. The incorporation of AI significantly improves the capabilities of cobots, allowing them to learn from experience and adapt to dynamic environments and unforeseen situations.