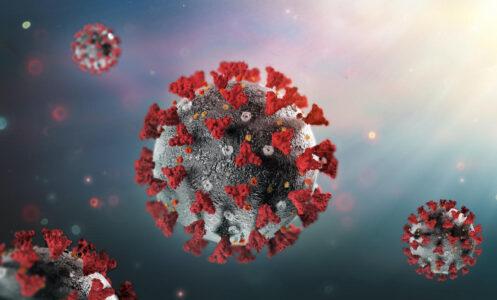

Transport is a very broad activity. Its effectiveness and efficiency have a direct impact on the quality of service perceived by the end customer and the bottom line of both suppliers and client companies.

As in any other area, there are strategic, tactical and operational decisions, depending on their time horizon, their reversibility and their unitary importance. Insourcing or outsourcing transport activities, dimensioning the vehicle fleet or defining the routes for each vehicle are some examples of relevant decisions in this context.

Furthermore, transport-related decisions are closely linked to other decisions. For example, the locations of future warehouses will determine the routes that vehicles can take to deliver or receive their cargo (so impacting the cost and the quality of service). Choosing a wrong location could be very expensive in the long run.

Why transport management is so complicated? The case of the vaccine

Taking as an example the real case of the transportation of coronavirus vaccines, let’s look at some elements that illustrate the complexity of the decisions that this activity requires and how this issue encompasses many more aspects than it may appear at first. As Bruce Y. Lee, a healthcare expert and Forbes contributor puts it, “The vaccine doesn’t magically jump from the lab to the patient’s arm.”

It is a logistical operation of unprecedented importance that must ensure for several months that the vaccine reaches all citizens who need it as quickly as possible, regardless of their location.

The extremely low temperature at which the vaccine must be stored poses a significant challenge, which not only imposes strict requirements on storage spaces and vehicles, but also pushes to minimize movements between the moment that they leave the factories and they are used. The difficulty of storage implies that transport must be synchornized with the availability of specialized and trained personnel to apply the vaccine.

Nor can it go unnoticed that the vaccines are a very valuable product, whose distribution must be carried out discretely and, therefore, the locations of warehouses and transport routes are kept secret.

Three decision levels

Strategic decisions are important decisions that determine all the others. In this context, they are difficult to change afterwards and usually require a high investment.

For example, a strategic decision related to transportation is to decide where to locate facilities, how many are needed, and how to dimension them. These aspects are key in any logistics network because they will condition the tactical and operational decisions that can be taken later.

If you do not adequately decide where to locate your warehouse, you will incur higher transport costs in daily operations. If you dimension for a greater capacity than really necessary, it will have been a useless investment; whereas in the opposite case, the expansion of the capacity will imply higher costs than a good initial planning.

Tactical decisions also play an important role in cost management and service quality, so not paying adequate attention to them can lead to higher costs or customer churn.

For example, the dimensioning of the delivery fleet. This decision not only implies the analysis of how many vehicles you need to satisfy the demand of your clients or if you might be interested in outsourcing this service. It is also very important to have a good forecast of demand and your growth expectations to plan these aspects for the following year.

Operational decisions have a great impact on the quality and service that customers ultimately receive. Choosing the best routes on a recurring basis based on short-term demand is key to meeting customer expectations, while containing costs and protecting margins.

Sometimes the short-term demand is known sufficiently in advance to define the routes of the vehicles to meet it. On other occasions, it will be necessary to make use of demand forecasting models and other data such as the traffic situation or real-time service delays. The more information that is available, the easier to manage costs and provide a better service.

The traditional approach

Supporting high-level decisions by using advanced analytics together with all the tools and information available is usually a good investment.

The traditional approach to solving problems consists in applying simple rules on spreadsheets, which can provide a good enough solution if the problem is not very complex and the total number of possibilities to analyze is relatively small. However, it is a slow process that allows only a few alternatives to be explored and makes the “what-if” analysis difficult, and therefore the solutions obtained can usually be improved.

Prescriptive analytics is proven to consistently deliver improvements over this approach.

A simple problem

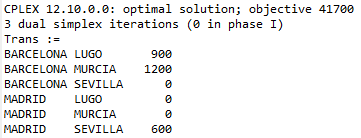

To illustrate the usefulness of advanced analytics in this context, suppose that our transport services have been hired to deliver certain cargo in Spain. Our task is to collect it in the factories and bring it to the customers at the lowest possible cost.

The factories in Madrid and Barcelona have a specific production capacity and customers in Lugo, Murcia and Seville have informed us of their demand. We know how much it would cost us to deliver the goods from each factory to customers and both factories produce the same, so it does not matter which one supplies to each customer.

| PLANT | PRODUCTION | CUSTOMER | DEMAND | UNIT TRANSPORT COST | |||||

| MADRID | 1.400 | LUGO | 900 | LUGO | MURCIA | SEVILLA | |||

| BARCELONA | 2.600 | MURCIA | 1.200 | MADRID | 39 € | 14 € | 11 € | ||

| VALENCIA | 2.900 | SEVILLA | 600 | BARCELONA | 27 € | 9 € | 12 € |

A simple rule of thumb for finding a solution would be to choose the least costly route and transport as much as possible on it. So Barcelona would serve Murcia and Lugo, and Madrid would serve Seville.

Good enough alternatives to this transportation plan can be explored manually, but this approach becomes ineffective when the problem grows, in which case the plan is more likely to be far from optimal.

The alternative: an optimization model

Alternatively, we can formulate this problem mathematically and build an optimization model to solve it.

Indices

p: plants

c: clients

Parameters

Op: capacity in each plant p

Dc: demand by each client c

CTpc: Unit transport cost from p to c

Variables

xpc: units delivered from p to c

z: total cost of transport

Minimize

![]()

Subject to

![]()

![]()

![]()

The solution in both cases is the same: Barcelona delivers to Lugo and Murcia and Madrid is the one that delivers the product to Seville. The total transport costs are 27×900 + 9×1,200 + 11×600 = € 41,700

A bigger problem

The above problem gets more complicated by considering a few more origins and destinations.

| PLANT | PRODUCTION | CUSTOMER | DEMAND | |

| MADRID | 1.400 | LUGO | 900 | |

| BARCELONA | 2.600 | MURCIA | 1.200 | |

| VALENCIA | 2.900 | SEVILLA | 600 | |

| ZARAGOZA | 400 | |||

| BILBAO | 1.700 | |||

| SALAMANCA | 1.100 | |||

| VALENCIA | 1.000 |

| UNIT TRANSPORTATION COST | |||||||

| LUGO | MURCIA | SEVILLA | ZARAGOZA | BILBAO | SALAMANCA | VALENCIA | |

| MADRID | 39 € | 14 € | 11 € | 14 € | 16 € | 82 € | 8 € |

| BARCELONA | 27 € | 9 € | 12 € | 9 € | 26 € | 95 € | 17 € |

| VALENCIA | 24 € | 14 € | 17 € | 13 € | 28 € | 99 € | 20 € |

Solving this problem manually is no longer so easy. A workable match may take more time to find, and exploring alternatives is not so obvious. Furthermore, the larger the dimension of the problem, the more likely it is that the manual solution found is far from optimal.

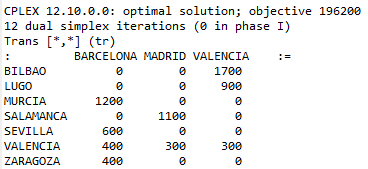

On the contrary, the previously proposed model solves this new case immediately.

If we had applied the previous simple rule again (choose the route with the lowest cost and use it to deliver as much product as possible) we would have started sending from Madrid all the demand coming from Valencia. The transport assignment could have been carried out manually but, now knowing the optimal solution, we can see that we would have got off to a bad start.

Reality is much more complex

The previous example shows that even in a simple (and unrealistic) problem the solutions that the human mind can come up with may be far from optimal.

When faced with the complexity of real transportation problems, the inefficiency of the “manual” methods is even more noticeable.

For example, on many occasions, there are consolidation centres, where cargo from various origins can be grouped together to fill up the trucks (full truck load, FTL), which requires coordinating truck loads and their arrivals at the consolidation centres.

Likewise, and of course, on many occasions it is necessary to coordinate transport activities with inventory management in different locations, in order to guarantee product availability without incurring high costs in storage and transport.

When forced to coordinate many activities like the ones mentioned, consider more links in the logistics chain, supply a greater variety of products using different methods of transport, etc., the traditional approach and spreadsheets can become insufficient.

In addition, not only are you working with problems of a greater dimension, but not all the data is always known. For example, customers do not always communicate a fixed amount and sufficiently in advance and oscillating fuel prices can make transport costs vary from one period to another.

Therefore, the options that offer predictive and prescriptive analytics can provide a lot of value to your transport activity, taking advantage of your resources and opportunities and mitigating the possible risks of the operation.