Today, with the skyrocketing price of electricity, the issue of electricity generation has come to the forefront.

While energy mix and technology improvements are the most influential aspects of power generation, advanced, predictive, and prescriptive analytics can play an important role in getting more out of existing or future installations.

We will now look at three examples of improvements achievable with advanced analytics at the design, operation, and maintenance levels of electrical installations.

Optimise Wind Farm Design

During conception, advanced analytics can contribute to the realisation of more efficient renewable installation designs. In particular, it can be applied to optimise the spatial organisation of offshore wind farms.

Wind turbines generate wake effects in the air downstream. Due to the energy extracted by the turbine, the wind speed is reduced over a certain area behind the wind turbine.

For this reason, a wind turbine located in the wake zone of another turbine will enter the wind at a lower speed and will have a lower efficiency. This effect is even more important in offshore wind farms where all wind turbines are at the same height.

The most natural way to arrange wind turbines on a wind farm is a simple grid. However, this simple organisation ensures an overlap of the wake zones of wind turbines located on the same lines or diagonals, resulting in yield losses. Alternatively, wind turbines could be spaced sufficiently far apart to avoid these overlaps, but this solution would reduce the total number of turbines installed in the wind farm and thus their electricity production.

Based on wind direction and wind force data, the most frequent wake effect zones can be evaluated for each possible wind farm site. With this data, prescriptive analytical techniques can be used to establish an optimal layout maximising the number of installed wind turbines and minimising wake effect disturbances for the most likely wind configurations. By applying these techniques, a wind farm can see its electricity generation increase with a lower or similar investment.

In the same way, it is also possible to optimise the maintenance paths of onshore wind farms or the cable collection of offshore wind farms. In both cases, the aim is to find a way to connect all wind turbines at a lower cost taking into account distances, land relief, and construction costs.

Speed up the Production of Hydroelectric Power Plants.

Advanced analytics methods can be applied to increase the efficiency of existing assets such as hydroelectric power plants.

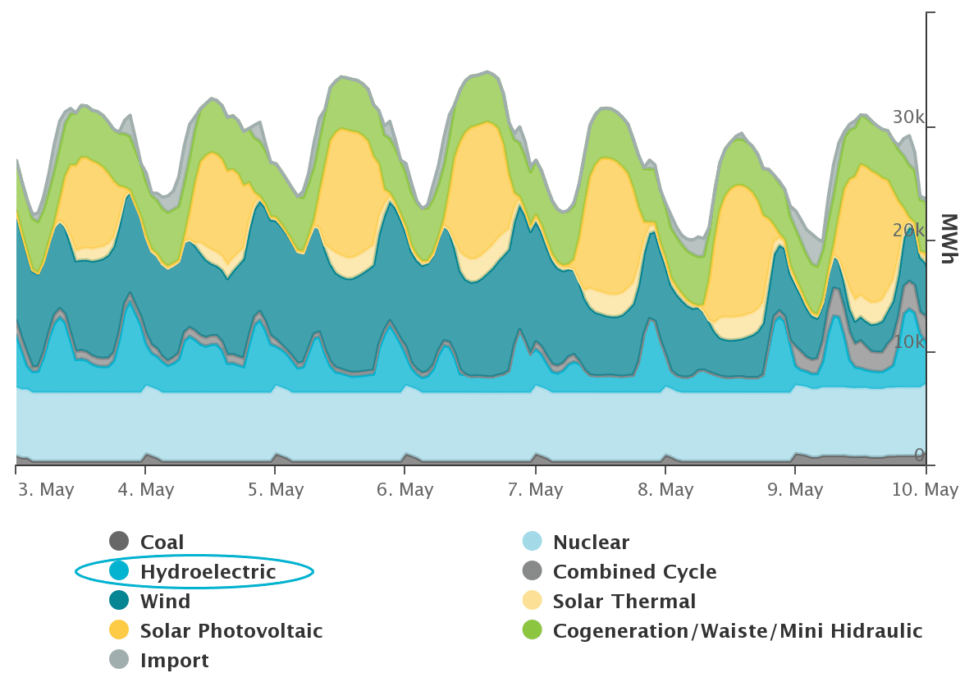

As a note, in the OMIE production chart, hydropower is able to adapt most of its production to demand to compensate for the variability of the other renewable productions. This ability is due to high and medium capacity reservoirs that can produce electricity on demand using their huge water reserves.

However, there is also a constant part that does not match the demand. This part corresponds to smaller reservoirs with storage capacities of a few hours or days of production. These reservoirs are usually located at different points in the basin of the same river so that the production of one plant has an effect on the quantity of water, arriving at the next a few minutes or hours later. This combined with low storage capacity makes it difficult to keep up with demand. For this reason, these plants tend to have a more or less constant production over time.

However, prescriptive analytics can use part of this storage capacity to optimise the production of these plants by taking into account the water displacements caused. Thus, by optimising a basin as a whole, these models can place a greater part of the production in the hours with the highest demand without affecting yields or completely emptying the reservoirs.

Similar methods can be used even for high-capacity reservoirs but with different approaches. Of course, these reservoirs have no problem locating their production at the daily level but they may need the support of advanced analytics to manage their water resources throughout the year. In this case, the models will have to approximate the demand and future inflows of water and recommend when it is preferable to produce more or, on the contrary, to limit and store water for future use.

Rationalise the Maintenance of Solar Panels.

Advanced analytics has practical applications in the maintenance area of power generation facilities.

For example, after analysing sensor data from photovoltaic panels, predictive analytics can identify signals and clues that precede a component failure and predict them some time in advance.

From this, it is possible to start implementing predictive maintenance to change defective components before they fail and to establish maintenance strategies:

- Mutualise predictive and reactive maintenance tasks with common aspects (same area, same component types) to use maintenance resources (human and material) more efficiently.

- Prioritise high-impact tasks and accept not attending quickly to some low-impact failures.

- Plan the various maintenance tasks over time to even out the workloads of employees and free up time for emergencies.

However, the implementation of these strategies faces significant planning difficulties. With more and more options for improving operations, finding efficient planning is a very complex puzzle for a human being to solve.

This is where prescriptive analytics comes in with optimisation algorithms that achieve efficient maintenance plans taking into account all constraints and balances between maintenance costs and production capacities.

These mathematical methods make it possible to reach an optimal balance between the above strategies in a reasonable amount of time and to generate flexible maintenance schedules in the medium and short term.