All companies, especially the larger ones, are undertaking an unstoppable digital transformation process. And it is not about incorporating technology for its own sake, but for their own survival: companies that will fall behind will disappear.

Among the most disruptive technologies is Artificial Intelligence with Advanced Data Analytics, which is playing an ever more important role in this digital transformation.

The Logistics segment is a little behind in the implementation of Artificial Intelligence, but the good news is that other sectors such as Retail, Food and Beverages, Energy, Automobile, Pharmaceutical, etc., can apply some techniques in their Logistics and Operations departments that are already in use by other areas.

These are the steps that leading companies broadly follow to accelerate their transformation and which also apply to Artificial Intelligence in Logistics:

1 – Identification of use cases

A “use case” is a specific activity in a company with a challenge or problem to solve. For example, use cases in Logistics could be related to last mile delivery or warehouse picking.

Cases can be as varied as the problems. In the case of last mile delivery, the challenge might be how to carry out this activity by traveling the shortest total distance, or using the minimum amount of vehicles without affecting the quality of the delivery service. And in the picking use case, the challenge may consist on shortening the routes that the operators or RPAs follow in the warehouse, so that the checking in and out of goods becomes cheaper and quicker.

In short, when we look for use cases, we are identifying activities with well-defined objectives such as reducing costs, improving service quality or increasing revenue.

An easy place to find these use cases in Logistics is in activities in which humans take care of planning tasks and resources, mainly in these areas:

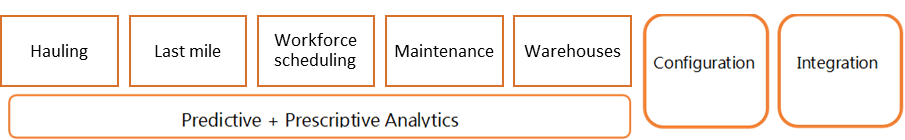

- Hauling

- Last mile routing

- Workforce scheduling

- Maintenance of vehicles or other assets

- Warehouses

Each of these areas could use people or computer applications to plan and allocate tasks, labour, vehicles, etc. When this activity is complex, decision makers tend to use very complicated spreadsheets or applications that are not fully adapted to the actual challenge. When this occurs along with significant room for performance improvement, that is a sign of a potentially good use case.

2 – Priorization

In any company, and especially in the Logistics area, there are dozens of digital transformation use cases that can be addressed by applying Artificial Intelligence. But most often, all these improvements cannot be executed at the same time due to budget limitations, capacity, technical feasibility due to inadequate data sources or pending integration requirements.

Hence, it is necessary to prioritize use cases, even defining the phases of the development of the solutions. These are the main criteria to take into account:

· ROI/ payback

It is about making a “business case”, in which we estimate the potential cost savings (or increased revenue, although this is rare in Logistics) brought by improving the use case processes.

Next, it would be necessary to estimate the cost of implementing a solution as a whole or in phases, and then calculate the solution’s ROI or payback. Using, Prescriptive Analytics techniques for example, savings can reach between 10% and 20%, depending on the volume and cost of the resources involved.

Considering these savings, payback can range from a few weeks to several months. Optimizing the haul transport of a fleet of 5 trucks is not the same as that of 3,000, and in many cases, the savings amount to hundreds of thousands of euros, even millions.

· Time To Market (TTM)

This is an aspect that is often overlooked in logistics despite being essential in some cases.

Time To Market is the time it takes to release a new service or product on the market. If a company is slow to launch new services, it will lose ground against its competition, and the opportunity to generate earlier income with the new service or its improvement.

A clear example in logistics is the case when a company wants to offer delivery guarantees to its customers, but the technology at its disposal does not allow them because they cannot plan deliveries optimally without incurring losses.

· Viability

It is necessary to check if the proposed solution is viable both from a technical and operational point of view. It is common to propose solutions that seem good to a use case at first but, for example, when the types of available data are analyzed, it is discovered that they are insufficient, or that the work environment requires continuous re-planning, with impossible response times unless different techniques are used.

In order to prioritize use cases after analyzing these three aspects, it is common practice to rate each one of them in a table and allocate weights according to the importance given to the ROI compared to the TTM, and eliminating or postponing those cases that are not viable.

And once the use cases have been prioritized, a “roadmap” or schedule with the estimated execution dates is placed, taking into account:

- Score in priority table

- Future viability

- Dependencies on previous use cases

- Project plans and phases

3 – Trials

This step is usually necessary to reduce risks and gradually roll out the solution.

Pilots are usually developed iteratively so that options, data sources, interfaces, etc. are tested, and in each iteration the results are validated against those expected and compared to previous solutions.

In the example of a warehouse staff shift use case, you would first want to conduct a trial in one facility until the solution was fully validated and the change in work dynamics was acceptable when the application was fully rolled out.

4 – Scaling and integration

Following on this example, after the solution is validated in the first warehouse, it can be deployed to the rest of the warehouses along with the necessary changes at the configuration level to take into account the peculiarities of each one, avoiding, if possible, different developments for different warehouses.

This “scaling” requires integration with the pre-existing applications in the company. This aspect is essential so that the solutions are not mere academic exercises, but are useful on a day-to-day basis and that users are, as far as possible, working in an environment that they feel familiar with.

Conclusion

These 4 steps describe in a simple way how to approach the transformation of the Logistics area of almost any sector. It is a process of continuous improvement, where it is essential that use cases are identified, prioritized and the solution development is planned on a roadmap. This roadmap is not immovable, it should be reviewed every 3 or 6 months because circumstances are changing, and new market challenges and technological innovations appear.