The industrial sector has always worked to reduce energy costs in production processes. At times when the price of energy is very high, this is even more important and can often lead to factory shutdowns while waiting for prices to fall.

In a factory, one of the key elements for cost reduction is the optimisation of production. That is where Artificial Intelligence comes into play to reduce energy costs.

Artificial Intelligence in Production Planning

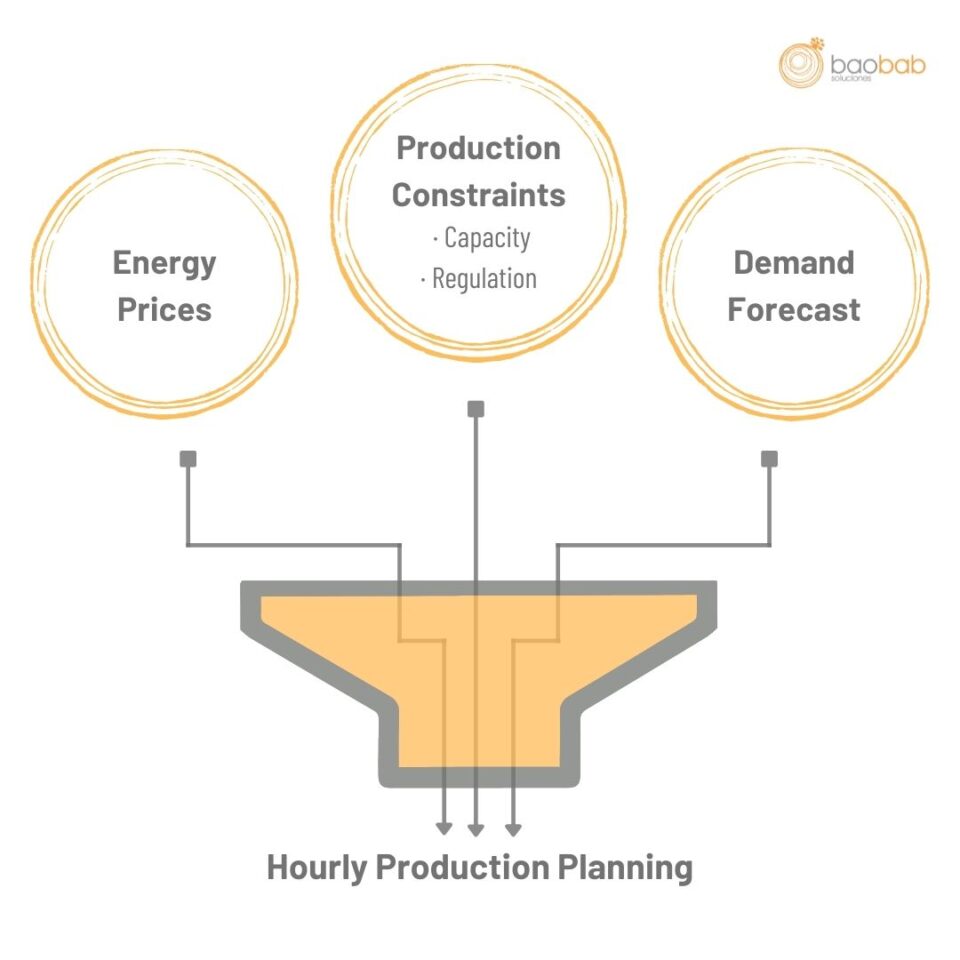

Production planning requires coordinating the availability of different resources (machines, people, materials and components) while respecting all technical constraints to deliver the planned quantities at the agreed times.

Artificial Intelligence makes it possible to obtain schedules that meet delivery commitments, but with a focus on efficiency and minimising inventories. Consideration is made, among other things, of order delivery dates, availability of workplaces, human and material resource requirements, and capacity utilisation forecasts. The aim is to balance the number of resources, minimise the manufacturing time, minimise penalties for delay, etc.

Production planning is a complex process, even if only the demand for the products to be manufactured is taken into account, something that would already justify the development of a tool based on Artificial Intelligence, it is even more justified when the price of energy is also taken into account, increasing the complexity of the problem and making it practically impossible for a human being to solve it without a tool.

Artificial Intelligence Techniques for Production Planning

Before continuing on how to incorporate energy pricing into production planning, it is worth explaining the two main lines or types of Artificial Intelligence tools that have been adopted:

- Predictive Analytics, mainly based on Machine Learning / Deep Learning: With extensive data, it is possible to “train” the tools to make predictions. The capacity to make predictions is fundamental for sizing factory resources to meet demand.

- Prescriptive Analytics is based on Operations Research (mathematical optimisation techniques, simulation, etc.). In manufacturing processes, a decision has to be made between a large number of options or possibilities. A human being can make a good decision to decide the production sequence or how many people you need in a shift; however, it is probably not the optimal decision. And in these areas, the difference between a good and an optimal decision translates into significant operational cost savings, corroborated by independent studies.

More Complexity in Production Scheduling with the “Energy Factor”.

There are several elements to consider when looking for savings in energy costs:

- Cost of energy in each hour or time interval where production takes place. It is also valid when cogeneration systems are employed.

- Consumption estimates of the machines according to their operating regimes.

These elements radically change production planning that only considers manufacturing demand. In this case, a break-even point has to strike between meeting demand and reducing energy costs.

Example of Potential Savings

In electro-intensive sectors such as metallurgy, chemicals, steel and industrial gases, energy costs can account for up to 50% of production costs.

For example, in industrial gases, baobab soluciones has built a planning optimisation tool for Air Liquid, with which it has achieved:

- Energy cost reductions of around 5-8%, depending on energy prices, saving its plants in Spain more than €2 million per year (with 2022 prices, the savings are much higher).

- Quick re-planning to take into account issues during production.

- Simulations creation, compare scenarios and what-if analysis.

Conclusions

One of the biggest challenges for the industry is the optimisation of energy use, not only to reduce costs in a highly volatile environment of prices for electricity, natural gas and other sources but also because of the need to reduce the carbon footprint.

In this context, we can apply Artificial Intelligence and, depending on the case, achieve savings in the range of 5%-20%, very much subject to fluctuations in energy prices.