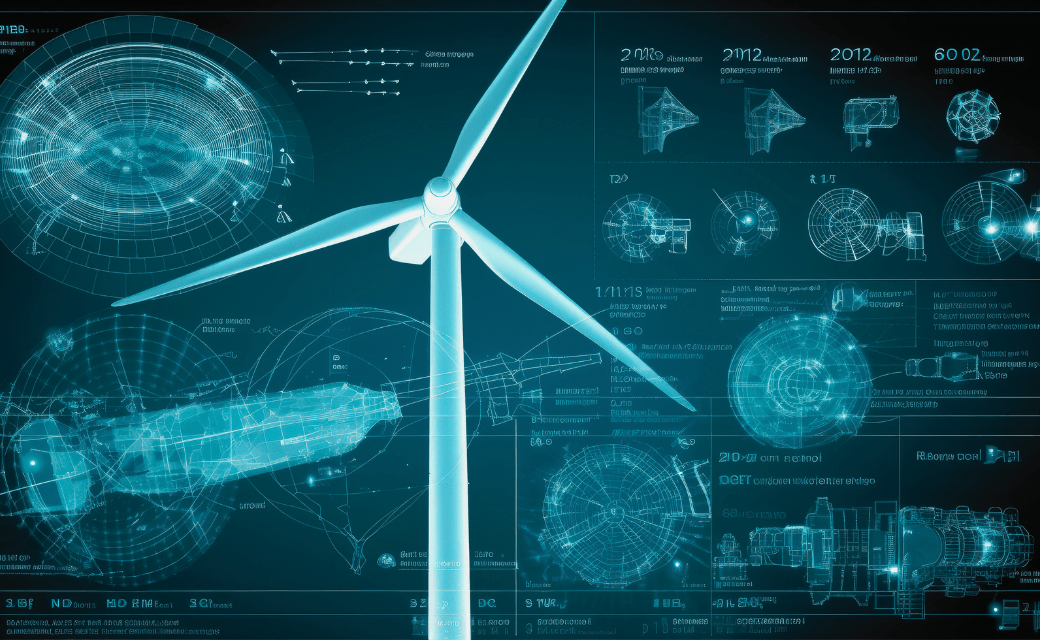

Discover how AI is transforming the way we sustainably manage and optimize our energy infrastructure.

In recent years, the Spanish energy industry has experienced a series of significant changes; where decarbonization, digitalization and decentralization are the main trends that are transforming the sector.

In this context, AI plays an increasingly relevant role, as it offers energy companies new opportunities to improve their efficiency, reduce their costs and increase their competitiveness.

Artificial Intelligence (AI) has emerged as a topic of great interest in recent times, experiencing great growth in recent years, to the point where its presence has become omnipresent in various facets of daily life. Its influence has been significantly manifested in a wide variety of industrial and technological sectors. One of the areas of special relevance in this context is the area of renewable energy. However, in this article, we will focus in particular on the use of AI to carry out predictive maintenance tasks in the context of wind energy.

How is predictive maintenance applied to wind energy?

Predictive maintenance constitutes an approach that involves the use of various techniques derived from Machine Learning (ML), a discipline belonging to the field of AI, with the purpose of identifying potential irregularities that may manifest in the operation of wind turbines. These techniques have a remarkable capacity to process substantial volumes of data from sensors located in the turbines, which capture a wide range of measurements, including vibrations, temperatures, pressures and other parameters of significant relevance for the optimal performance of said devices.

The use of these ML techniques, by virtue of the information obtained from the sensors and their corresponding analysis, makes it possible to detect patterns that denote deviations or irregularities in the traditional behavior of the turbines. This ability to anticipate potential anomalies makes it possible to implement corrective actions at an early stage, preventing more severe circumstances such as breakdowns, excessive wear and other contingencies that could arise in the future.

The benefits associated with the use of predictive maintenance are significant and include:

- The ability of operators to identify and prevent possible failures before they manifest themselves concretely, thus avoiding larger problems and, therefore, reducing the costs derived from unscheduled repairs.

- The minimization of unplanned periods of inactivity of the turbines by preventing breakdowns and failures, which in turn translates into a more constant and reliable operation of said devices, and consequently, in a continuous and stable generation of energy.

- The advantages produced by the previous points generate substantial improvements in energy production and, therefore, greater profitability over time.

In summary, the implementation of ML-based techniques in the context of wind turbine maintenance not only optimizes the operation of these infrastructures, but also positively affects the economic and long-term sustainability aspects inherent to the generation of wind power.

Click on the link and learn more about us and how we have successfully applied Artificial Intelligence solutions in companies like yours.