Intelligent production scheduling is crucial for retailers involved in product manufacturing. If you’re in this sector, you’ve probably faced challenges like quality control, maintenance, and task sequencing on the production line. Production scheduling is like a complex puzzle that needs constant adjustment to meet demand. In 2023, the production and manufacturing industry made up 28% of the European Union’s GDP, so solving these issues is vital for boosting product margins and retail ROI. That’s where Smart Production Scheduling steps in, offering quicker and more effective solutions.

Curious about how these technologies can benefit your company?

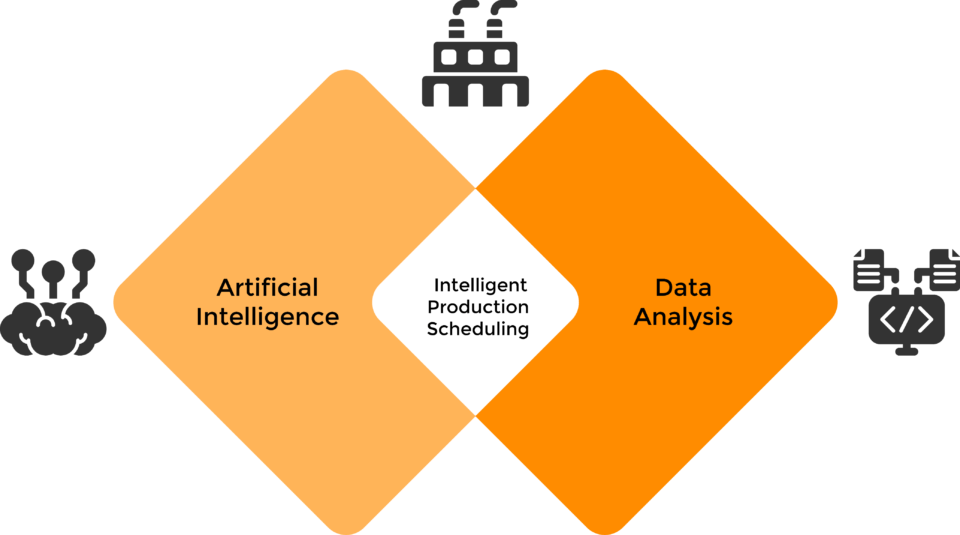

What’s Intelligent Production Scheduling (IPP)?

IPP is an approach to production planning and management that harnesses advanced tech like artificial intelligence (AI) and data analytics to optimize and automate production scheduling in factories or plants.

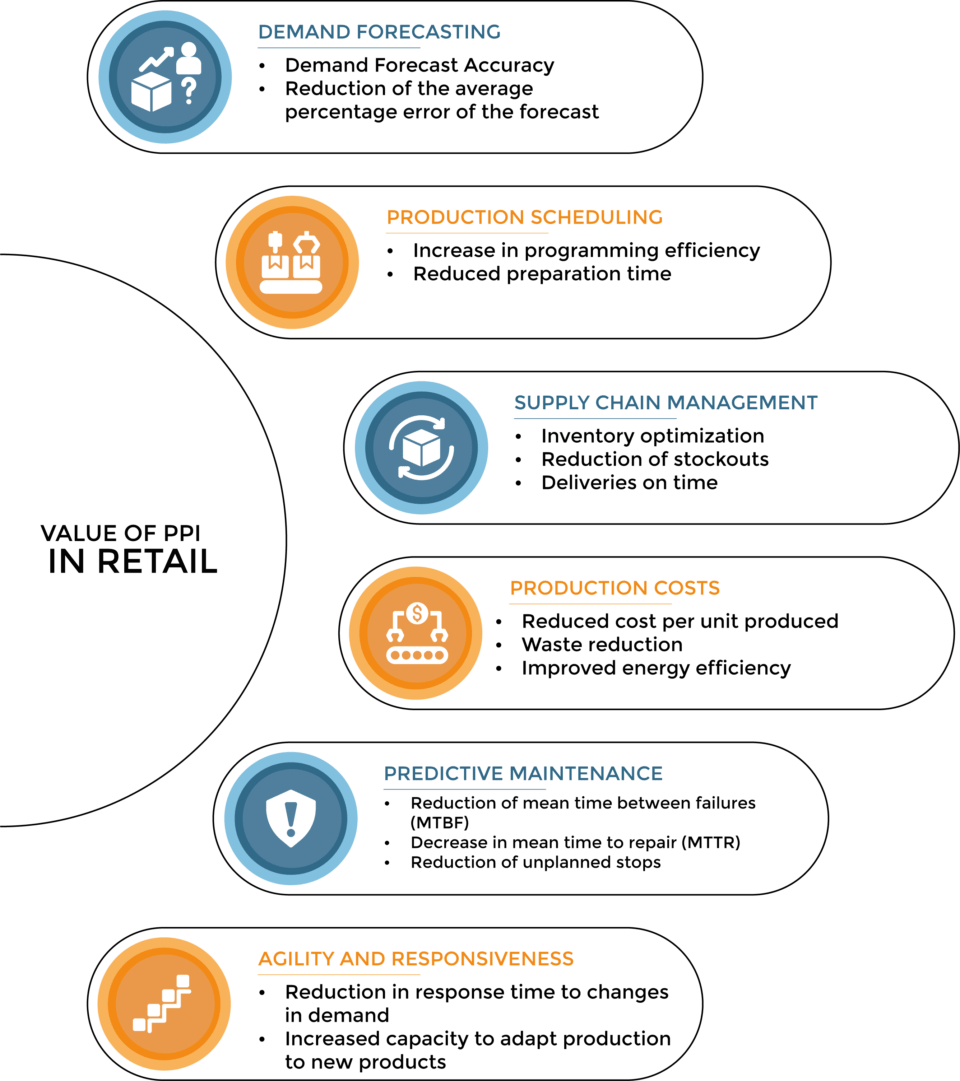

What are the advantages for retail?

Implementing AI and data analytics in production planning brings several benefits that can revamp manufacturing operations and increase overall efficiency. Here are the key advantages:

How does it work?

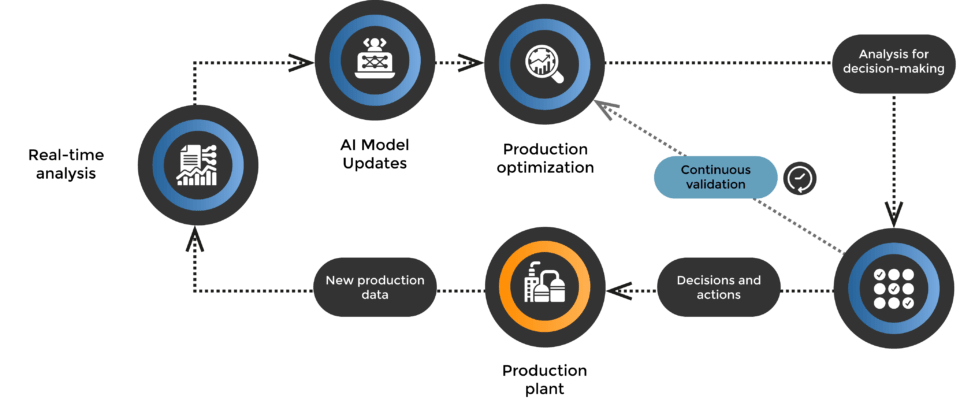

Intelligent Production Scheduling is a sophisticated, ongoing process that continually improves productivity.

1. Production plant:

The production floor is the epicenter where diverse data sources converge, from sensors in machinery to production logs and supply chain data. This raw data is a mine of valuable information about the current state of manufacturing operations.

2. New production data:

As manufacturing progresses, new production data is constantly generated that reflects real-time changes in machinery performance, product quality and other key factors.

3. Real-time analysis:

The cornerstone of Intelligent Production Scheduling (IPP) is the real-time analysis of this production data. Using artificial intelligence (AI) algorithms and data analysis tools, patterns are continually sought, trends are identified, and anomalies are detected.

4. AI Model Updates:

Based on this real-time analysis, the PPI AI model is constantly updated, learning from the data to improve the prediction and optimization of production processes.

5. Production optimization:

Using the updated AI model and real-time data, PPI optimizes production planning, adjusting plans, allocating resources efficiently and making strategic decisions to maximize productivity.

6. Analysis for decision-making:

In addition to automatic optimization, PPI provides information and analysis to support human decision-making. Users can access dashboards, reports and visualizations that show production performance and help identify areas for improvement.

7. Continuous validation:

PPI performance is continually validated by monitoring results and adjusting the AI model as necessary to ensure optimal performance.

8. Decisions and actions:

Ultimately, PPI empowers users to make informed decisions and proactive actions. With analysis and recommendations provided by the system, managers and operators can adjust processes, resolve problems, and optimize plant performance.

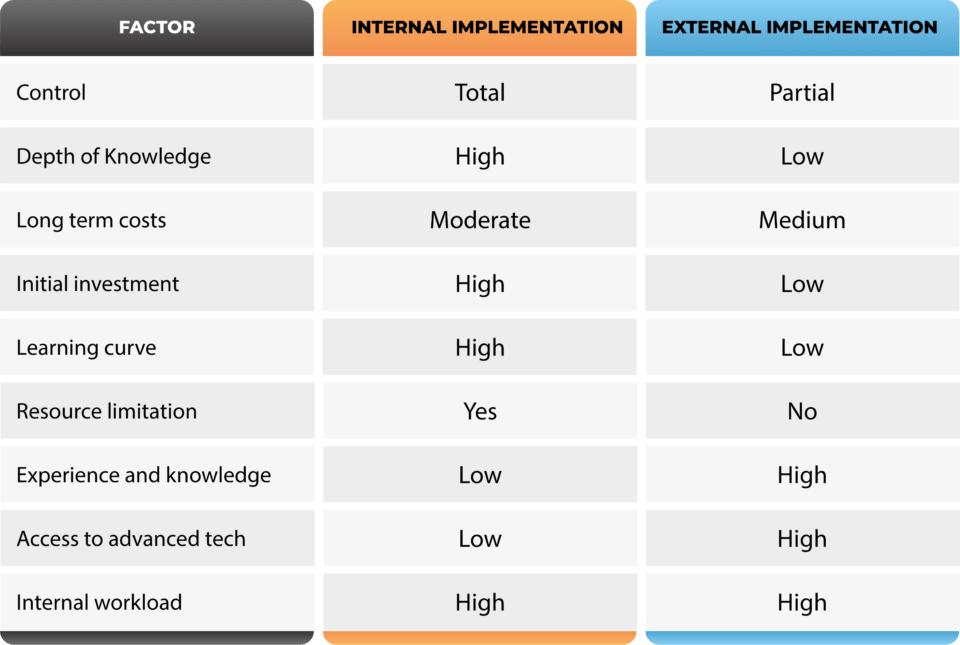

The decision to implement Intelligent Production Planning (IPP) in-house or hire an experienced third-party provider is crucial to the success of the initiative. Both options have advantages and disadvantages that should be carefully evaluated before making a decision.

At baobab soluciones, we understand the challenges businesses face when adopting new technologies, and we are committed to supporting you every step of the way. We have a team of highly trained professionals with vast experience in the development and implementation of technological solutions in various industries, including retail sector. We are prepared to offer you personalized solutions that adapt to your specific needs and exceed your expectations. You can trust us to guide you through this process and help you successfully achieve your business goals.

Intelligent Production Scheduling is indispensable for any retail company striving to stay competitive in a dynamic market. Turning data into smart strategic and operational decisions is key to achieving efficient, sustainable, and profitable production.